Overview:

DSY-V-40.5 inflatable switchgear has the advantages of compact structure, fully enclosed, fully insulated, long life, maintenance-free, small space, reliable, and not affected by the working environment. It is widely used in industrial and civil cable ring networks and power supply system terminals.

It is particularly suitable for small and medium-sized secondary substations, switchgear, factories and mines, airports, railways, residential areas, high-rise buildings, highways, subway stations, tunnel construction and other industries.

Comply with the specified national standards: EC60265, IEC60298, IEC60420, IEC60694, IEC60056, DIN47636 National industry standards: GBT11022-1999, GB3906-2006, GB3804-204, GB16926-2009 GB/T11023-1999, GB1984-2003, GB1985-2004, DL/T404-2007

Structural Characteristics:

- The dust collector of the gas cabinet adopts high-quality 2mm thick stainless steel housing.

- The stainless steel plate is cut by optical fiber laser and welded by the world’s leading welding robot to ensure the sealing of the dust collector.

- The gas box is filled with SF6 gas and undergoes synchronous vacuum packaging leakage detection; the high-voltage load switch, grounding switch, circuit breaker insulation layer and other switch active components and bus ducts are sealed in the stainless steel gas box, and the waterproof grade of the gas cover reaches P67. The dust collector is equipped with a glass diaphragm. When the internal pressure of the switch exceeds a certain level, it can be discharged from the explosion-proof port below, which can effectively avoid the harm to people, cables and other switch cabinets in the distribution station.

Normal Wroking Condition:

- Average altitude: ≤ 1500m

- Working temperature: -35℃~+40℃

- Air humidity: daily average ≤ 95%, monthly average s90%

- Earthquake resistance: 9 degrees, horizontal instantaneous speed of road surface < 0.4g, vertical instantaneous speed of road surface < 0.3g No strong vibration and impact, and sites with fire accidents and explosion risks

Gas-insulated switchgear adopts the most Optimized Design:

- Switchgear dimensions: width 600*depth 1150*height 2200mm

- The circuit breaker adopts vacuum breaking technology and SF6 gas insulation

- The three-position disconnector is grounded by closing the circuit breaker,

- It does not require gas filling or replenishing at the installation site

- The product has been operating reliably for 30 years

Full-function Structure:

- The role of gas-insulated switchgear in connecting, isolating or grounding:

- It plays a role in connecting the primary and secondary distribution networks

- Dual power automatic switching (ATS)

- Circuit breaker realizes automatic reclosing

- Cable connection is made at the front lower part of the switchgear

Online protection:

- The gas-insulated switchgear has the multi-functional requirements of smart grid

- Environmental online monitoring (temperature, humidity, intrusion…)

- Compatible with all brands of protection devices

- Provide highly integrated smart switchgear solutions

Product characteristics:

Safety

- The switch cabinet is equipped with complete mechanical locking and electrical interlocking functions.

- The gas box and cable room structure meet the arcing requirements.

- The cabinet grounding continuity is good

Reliable

- The stainless steel gas box has a protection level of IP67, and there is no failure during the life cycle without air replenishment.

- The design strength of the gas box meets the requirements of high altitudes of 5000m and below.

- The operating mechanism salt spray test meets 720 hours

Anti-fouling and Anti-dampness

- Suitable for operation in industrial dirty, salty and humid environments

- Switch cabinet anti-corrosion level: C4 on land and C4H at sea.

- All connections between secondary components use moisture-proof, moisture-proof and mildew-proof connectors

Intelligent Management

- Provide intelligent solutions to facilitate digital upgrades

- Provide selectable online monitoring functions such as switch status, mechanical properties, vacuum status, temperature and partial discharge

- Online real-time monitoring of IT and OT technologies

- Meet remote operation, monitoring and management

- Obtain installation instructions through QR code

Security Design:

Circuit Breaker

- Vacuum circuit breakers meet the requirements of GBT1984 standard

- Use vacuum breaking technology and SF6 gas insulation

- When the vacuum circuit breaker is in the closed position, the three-station isolating switch has mechanical or electrical locking function in any position of closing/isolating/grounding

Three-station Isolation Switch

- At the same time, the moving contact of the three-station isolation switch can only be in one of the positions of closing-opening (isolating)-grounding

- The three-station isolation switch achieves grounding closing by closing the circuit breaker

Cable House

- The grounding switch and the cable house have a complete mechanical locking scheme. The cable house door can only be opened when the grounding switch is in the grounding position to prevent accidental entry into the live interval

- When the cable is live, the grounding switch is locked and the cable house door cannot be opened. The cable house can only be entered when the power is off and it is safe

Ground Continuity

- The primary grounding circuit and the secondary grounding circuit are connected to the grounding grid separately

- The grounding continuity of the accessible part is good to ensure personnel safety

Arc Design

- The gas box and cable room walls are designed with special arc-proof design

- The gas box pressure relief channel is designed at the bottom of the gas box

- The cable room pressure relief channel is designed at the rear of the cabinet

- All arcing pressure is released to the cable trench to ensure the safety of personnel in front of and behind the cabinet

Bus Connection Scheme:

- Connect through the side of the inner cone bushing, or connect through the top of the outer cone bushing

- The inner cone scheme can achieve:-left connection-right connection

- Two-way connection on the left and right sides

- The outer cone scheme can achieve two-way connection on the left and right sides

- No need to inflate or replenish gas when connecting the busbar at the user’s site

- Under normal conditions, the rated current of the busbar is 1.1 times of 1250A

Recycling:

Committed to environmental protection, the product has passed the IS014001 international environmental management system certification and strictly implements the standard.

- Recycling and Scrapping

The design and manufacture of the DSY-V series switchgear meets the requirements of the national standard GB/T3906 and the international standard IEC62271200; at the end of the product life cycle, the SF6 gas is recycled and reused according to relevant standards. - Sustainable Development

DSY-V series switchgear continuously reduces the use of SF6 during the manufacturing process and does not use SF6 gas during the installation process;

All products are made of 100% recyclable materials; self-powered relays and devices are provided to avoid additional energy consumption.

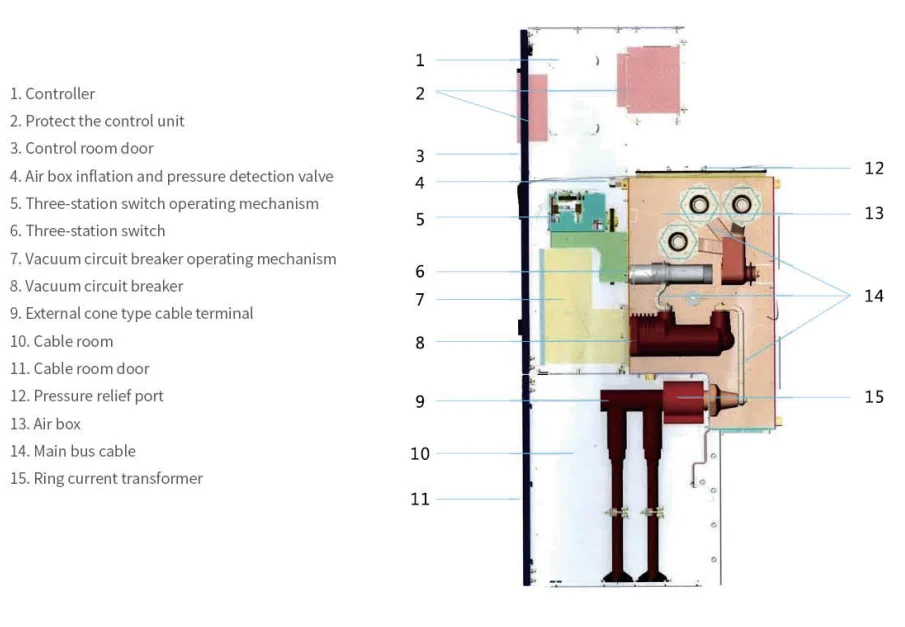

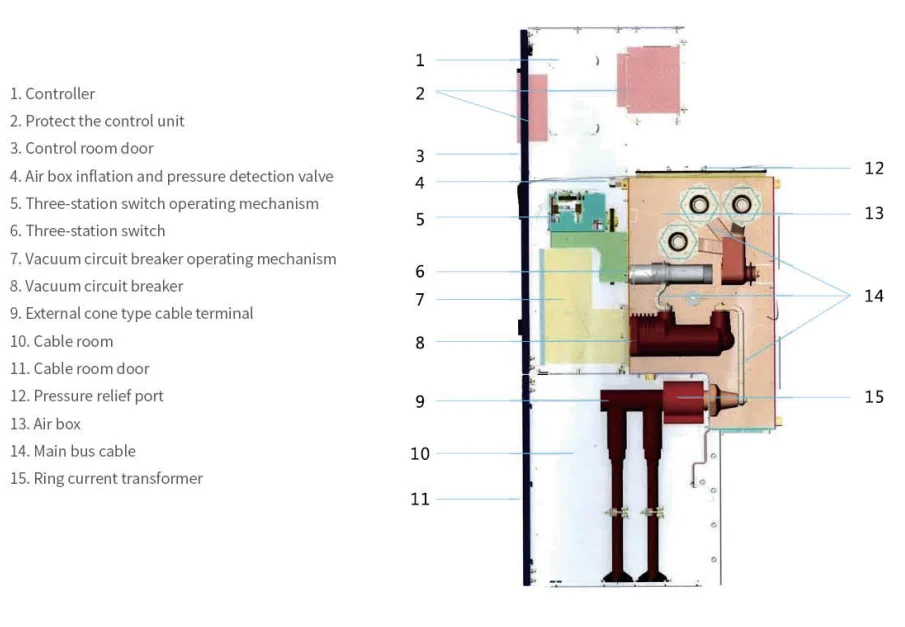

Diagram:

DSY-V-40.5 Gas-insulated Switchgears

隐藏域元素占位

Subcategory

Contact Us

- 产品描述

-

- Commodity name: DSY-V-40.5 Gas-insulated Switchgears

DSY-V-40.5 Gas-insulated switchgear is designed and produced in accordance with GB and IEC standards. It adopts a fully insulated and fully sealed structure and is suitable for harsh environments such as dirt, salt spray, humidity and high altitude. A variety of solutions can meet more stringent requirements.

Overview:

DSY-V-40.5 inflatable switchgear has the advantages of compact structure, fully enclosed, fully insulated, long life, maintenance-free, small space, reliable, and not affected by the working environment. It is widely used in industrial and civil cable ring networks and power supply system terminals.

It is particularly suitable for small and medium-sized secondary substations, switchgear, factories and mines, airports, railways, residential areas, high-rise buildings, highways, subway stations, tunnel construction and other industries.

Comply with the specified national standards: EC60265, IEC60298, IEC60420, IEC60694, IEC60056, DIN47636 National industry standards: GBT11022-1999, GB3906-2006, GB3804-204, GB16926-2009 GB/T11023-1999, GB1984-2003, GB1985-2004, DL/T404-2007

Structural Characteristics:

- The dust collector of the gas cabinet adopts high-quality 2mm thick stainless steel housing.

- The stainless steel plate is cut by optical fiber laser and welded by the world’s leading welding robot to ensure the sealing of the dust collector.

- The gas box is filled with SF6 gas and undergoes synchronous vacuum packaging leakage detection; the high-voltage load switch, grounding switch, circuit breaker insulation layer and other switch active components and bus ducts are sealed in the stainless steel gas box, and the waterproof grade of the gas cover reaches P67. The dust collector is equipped with a glass diaphragm. When the internal pressure of the switch exceeds a certain level, it can be discharged from the explosion-proof port below, which can effectively avoid the harm to people, cables and other switch cabinets in the distribution station.

Normal Wroking Condition:

- Average altitude: ≤ 1500m

- Working temperature: -35℃~+40℃

- Air humidity: daily average ≤ 95%, monthly average s90%

- Earthquake resistance: 9 degrees, horizontal instantaneous speed of road surface < 0.4g, vertical instantaneous speed of road surface < 0.3g No strong vibration and impact, and sites with fire accidents and explosion risks

Gas-insulated switchgear adopts the most Optimized Design:

- Switchgear dimensions: width 600*depth 1150*height 2200mm

- The circuit breaker adopts vacuum breaking technology and SF6 gas insulation

- The three-position disconnector is grounded by closing the circuit breaker,

- It does not require gas filling or replenishing at the installation site

- The product has been operating reliably for 30 years

Full-function Structure:

- The role of gas-insulated switchgear in connecting, isolating or grounding:

- It plays a role in connecting the primary and secondary distribution networks

- Dual power automatic switching (ATS)

- Circuit breaker realizes automatic reclosing

- Cable connection is made at the front lower part of the switchgear

Online protection:

- The gas-insulated switchgear has the multi-functional requirements of smart grid

- Environmental online monitoring (temperature, humidity, intrusion…)

- Compatible with all brands of protection devices

- Provide highly integrated smart switchgear solutions

Product characteristics:

Safety

- The switch cabinet is equipped with complete mechanical locking and electrical interlocking functions.

- The gas box and cable room structure meet the arcing requirements.

- The cabinet grounding continuity is good

Reliable

- The stainless steel gas box has a protection level of IP67, and there is no failure during the life cycle without air replenishment.

- The design strength of the gas box meets the requirements of high altitudes of 5000m and below.

- The operating mechanism salt spray test meets 720 hours

Anti-fouling and Anti-dampness

- Suitable for operation in industrial dirty, salty and humid environments

- Switch cabinet anti-corrosion level: C4 on land and C4H at sea.

- All connections between secondary components use moisture-proof, moisture-proof and mildew-proof connectors

Intelligent Management

- Provide intelligent solutions to facilitate digital upgrades

- Provide selectable online monitoring functions such as switch status, mechanical properties, vacuum status, temperature and partial discharge

- Online real-time monitoring of IT and OT technologies

- Meet remote operation, monitoring and management

- Obtain installation instructions through QR code

Security Design:

Circuit Breaker

- Vacuum circuit breakers meet the requirements of GBT1984 standard

- Use vacuum breaking technology and SF6 gas insulation

- When the vacuum circuit breaker is in the closed position, the three-station isolating switch has mechanical or electrical locking function in any position of closing/isolating/grounding

Three-station Isolation Switch

- At the same time, the moving contact of the three-station isolation switch can only be in one of the positions of closing-opening (isolating)-grounding

- The three-station isolation switch achieves grounding closing by closing the circuit breaker

Cable House

- The grounding switch and the cable house have a complete mechanical locking scheme. The cable house door can only be opened when the grounding switch is in the grounding position to prevent accidental entry into the live interval

- When the cable is live, the grounding switch is locked and the cable house door cannot be opened. The cable house can only be entered when the power is off and it is safe

Ground Continuity

- The primary grounding circuit and the secondary grounding circuit are connected to the grounding grid separately

- The grounding continuity of the accessible part is good to ensure personnel safety

Arc Design

- The gas box and cable room walls are designed with special arc-proof design

- The gas box pressure relief channel is designed at the bottom of the gas box

- The cable room pressure relief channel is designed at the rear of the cabinet

- All arcing pressure is released to the cable trench to ensure the safety of personnel in front of and behind the cabinet

Bus Connection Scheme:

- Connect through the side of the inner cone bushing, or connect through the top of the outer cone bushing

- The inner cone scheme can achieve:-left connection-right connection

- Two-way connection on the left and right sides

- The outer cone scheme can achieve two-way connection on the left and right sides

- No need to inflate or replenish gas when connecting the busbar at the user’s site

- Under normal conditions, the rated current of the busbar is 1.1 times of 1250A

Recycling:

Committed to environmental protection, the product has passed the IS014001 international environmental management system certification and strictly implements the standard.- Recycling and Scrapping

The design and manufacture of the DSY-V series switchgear meets the requirements of the national standard GB/T3906 and the international standard IEC62271200; at the end of the product life cycle, the SF6 gas is recycled and reused according to relevant standards. - Sustainable Development

DSY-V series switchgear continuously reduces the use of SF6 during the manufacturing process and does not use SF6 gas during the installation process;

All products are made of 100% recyclable materials; self-powered relays and devices are provided to avoid additional energy consumption.

Diagram:

Next Page

We Provide More Services That Make Sure Your Projects Safe, Reliable And Efficient